Feasibility study

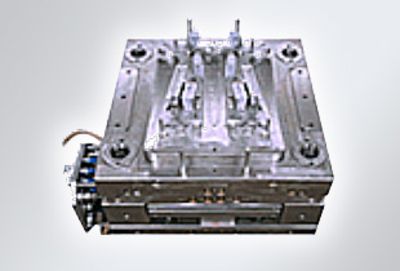

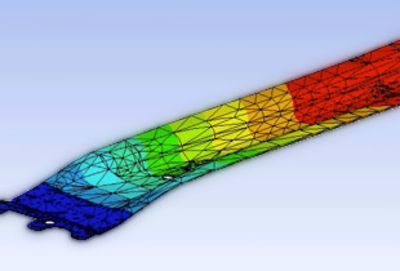

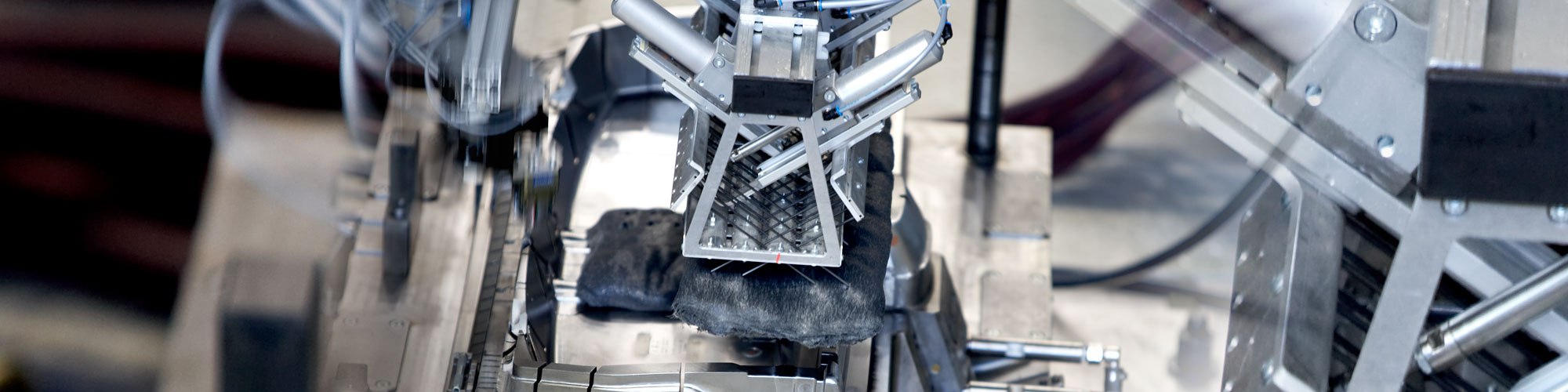

Do you have any problems with weight or costs? Or possibly both? Are you unsure whether your part or your idea can actually be realized in plastic? We provide you with a sound basis for decisions, taking account of both technical and commercial requirements, from the first estimate to a detailed feasibility study.