Taking off into a new production era

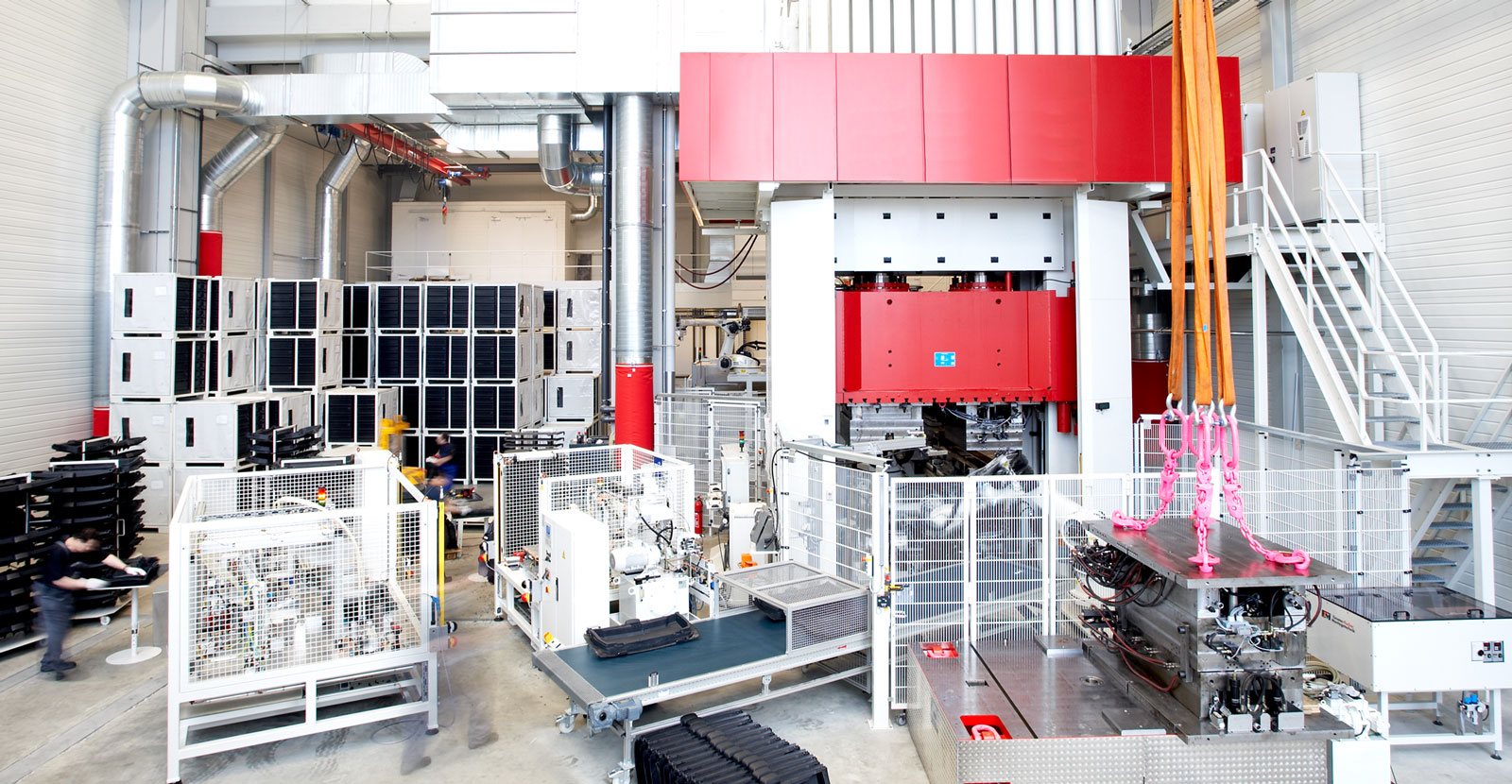

WEBER FIBERTECH is entering a new era in production with the delivery of the new injection molding machine from Krauss Maffei. The SGM 1600 injection...

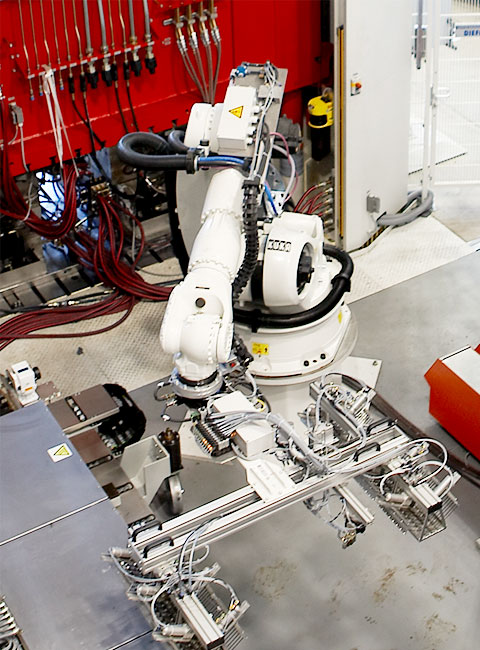

The WEBER FIBERTECH manufacturing plant in Markdorf, a small town in the far south of Germany, houses a modern and fully automated production line for parts up to two square meters in size. More than a million parts manufactured to date are clear confirmation that this innovative lightweight design technology is fit for serial production. The compounding plant which is integrated in the production line gives WEBER FIBERTECH considerable flexibility to adapt the material precisely to the specific requirements of each individual part – thus further expanding the wide range of potential applications. Apart from the automotive industry, our lightweight design technology is well-established in the aviation, building, transport and engineering sectors. It is also in considerable demand in electrical equipment, engine construction, agricultural implements and alternative energy systems.

You formulate an inquiry, outline your idea – and we search for the solution that best meets your needs. We develop your part, carry out feasibility studies based on detailed computations and simulations, optimize the part from both a technical and a commercial perspective, produce the first samples, provide you with functional, production quality prototypes, perform component tests and – last but not least – manufacture and supply your part in any desired quantity. We share our longstanding expertise in lightweight design with our customers and support them in the pursuit of their weight reduction, quality and economy targets.

Rough structural concept, guide prices and completion dates

Efficient provision of the required services

Detailed structural concept, rough dimensioning

Validated structural concept

Efficient provision of the required services

Representation of the design, weight, geometry and function

Prototype & production molds and equipment

Preproduction samples manufactured in an automated process

Tensile, drop and sled tests

Manufacture of E-LFT parts in medium-to-high volumes

Are you searching for a competent partner for lightweight design? Would you like to substitute a metal part for plastic? Is the strength of a conventionally manufactured plastic part causing you problems or are your duroplastic systems too expensive? Are you on the lookout for an affordable, tried-and-tested serial production method?

If so, why not contact us and profit from Weber Fibertech’s extensive expertise in the field. Take advantage of our know-how and our many years of practical experience when it comes to component layout and design, materials and serial production. Put us to the test – our experts will be pleased to discuss the opportunities and potential benefits of a partnership with Weber Fibertech with you in person.

Friedbert Schmitt

Managing Director, Weber Fibertech

Our headquarters and production facility are situated in Markdorf, in the hinterland of beautiful Lake Constance and only a short drive from both Austria and Switzerland.

Weber Fibertech GmbH

Daimlerstrasse 5

88677 Markdorf

Germany

Phone

+49 7544 963-6316

info@weber-fibertech.com

Plan your journey