Production projects

From prototype to successful serial production

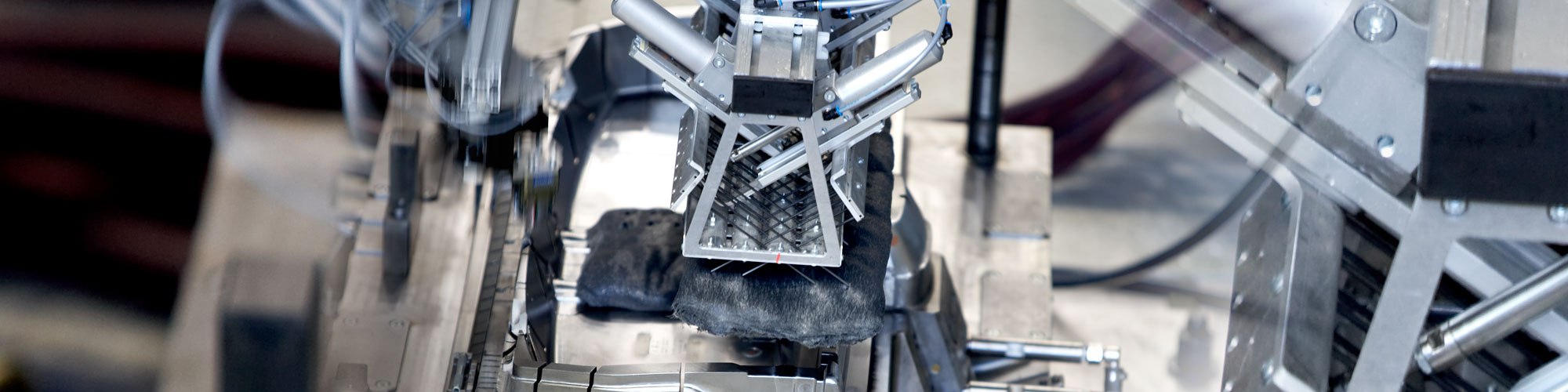

The process is based on long fiber thermoplastic technology, which gives you considerable flexibility in terms of design and structure. Glass or carbon fibers are added to the thermoplastic matrix material via our own compounding plant; owing to the gentle production process, these fibers remain intact for much longer than is the case, for instance, with conventional injection molding. The base material alone results in improved strength and stiffness of the parts.

If necessary, continuous (endless) glass or carbon fibers – which increase the strength of a part locally so that it fulfills crashworthiness requirements – are incorporated into this basic LFT structure as structural reinforcement.

Large-sized parts, as a substitute for sheet metal parts or sheet metal shell structures, can be economically produced using this technology. Developers also have the option of integrating functional elements directly into the process, enabling certain installation and testing steps to be eliminated.

Development projects

Application-oriented research & development projects

The aim of Weber Fibertech’s research and development activities, with the focus on lightweight design, is to promote lightweight design technologies through application-oriented development projects.

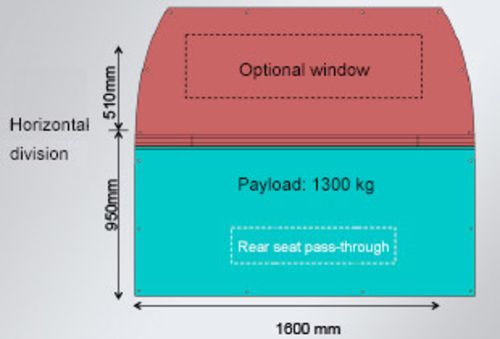

The upcoming trend towards electric mobility in the automotive industry has added further impetus to our specialization in lightweight design. Fiber composites will play a crucial role in tomorrow’s world. The direction is clear: our engineers will be called upon to apply their expertise in material mechanics, simulation, structural mechanics and bonding and joining technologies. Together with our customers, we will endeavor to develop lightweight, structurally stable parts with a high level of integration.

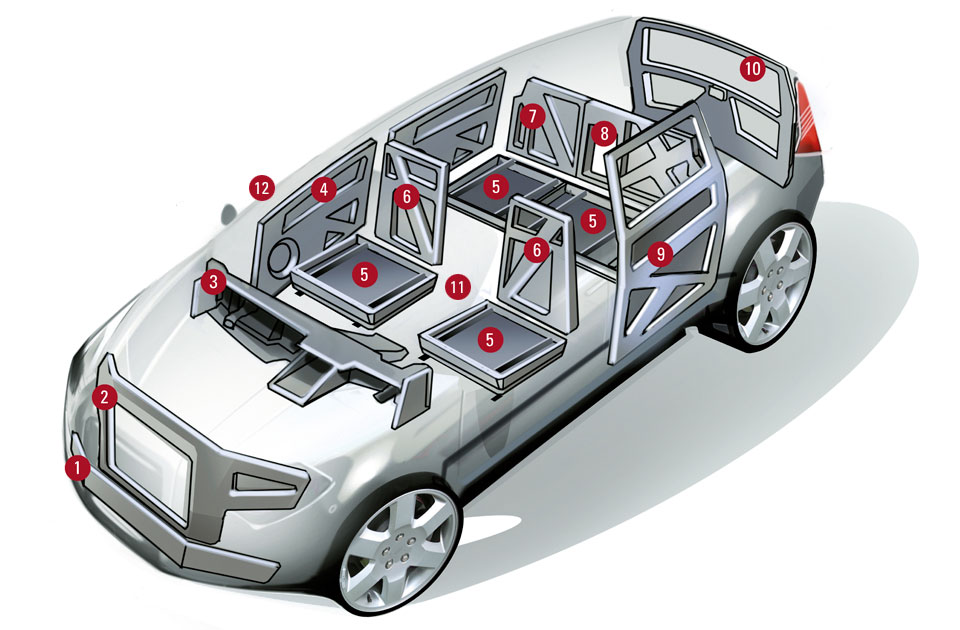

Solutions for automotive applications

1. Bumper

2. Front end

3. Dashboard

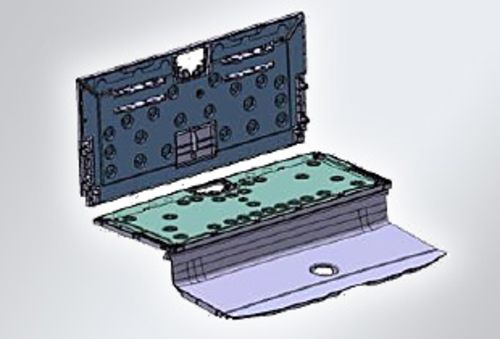

4. Door module

5. Seat shell

6. Seat back

7. 1/3 rear seat back

8. 2/3 rear seat back

9. Sliding door

10. Tailgate

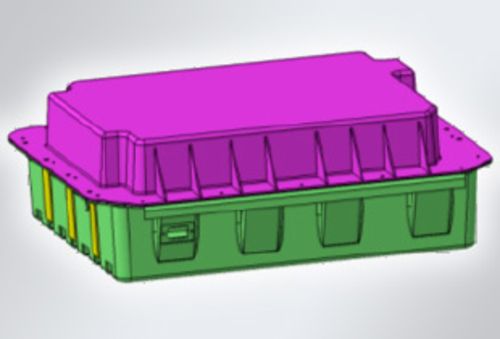

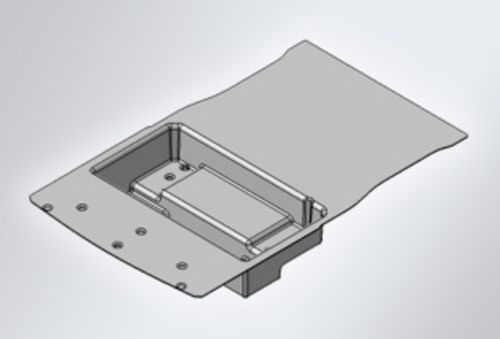

11. Battery tray

12. Roof systems

Feasibility study

We provide you with a sound basis for decisions

We get together with our customers to formulate answers to all questions arising from the selection, design and assessment of process chains for the manufacture of fiber composite parts. In addition to individual technology assessments including investment consulting and the preparation of feasibility studies, we carry out market studies to provide you with an overview of the latest state of the art as a sound basis for decisions.

Amassed expertise in interdisciplinary project teams

Our project teams promise to execute your project reliably and on time. Contact us for more information! Our experts will be pleased to discuss the opportunities of a partnership with Weber Fibertech with you in person.

Contact us