The E-LFT process

E-LFT – a combination of EF and LFT

In the search for processes that reconcile the apparent contradiction between stiffness, strength, long-term stability, weight and costs better than conventional materials, we decided to break free from the limitations of traditional thinking. The outcome: our E-LFT process, which WEBER FIBERTECH has made fit for serial production during ten years of intensive research and development.

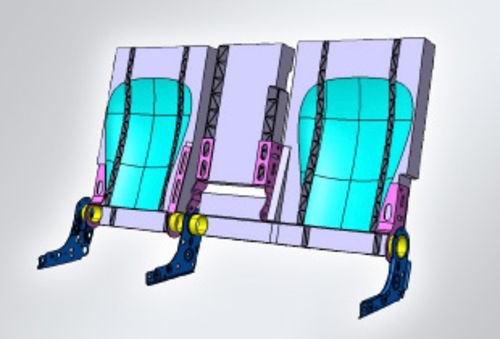

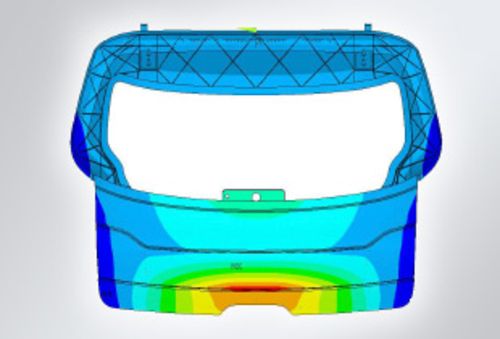

The process is based on long fiber thermoplastic technology, which gives you considerable flexibility in terms of design and structure. Continuous (endless) fibers, which increase the strength of a part so that it fulfills crashworthiness requirements, are incorporated into this basic structure as structural reinforcement. Apart from the greater design freedom, developers also have the option of integrating functional elements directly into the process, enabling certain installation and testing steps to be eliminated.

The result: parts weighing no more than half the average for conventional components, depending on the material, with no increase in cost and comparable or superior in terms of safety.

The production process

Efficient manufacturing technology and short cycle times

The process is based on long fiber thermoplastic technology, which gives you considerable flexibility in terms of design and structure. Continuous (endless) fibers, which increase the strength of a part in the areas relevant for the various load cases so that it fulfills crashworthiness requirements, are incorporated into this basic structure as structural reinforcement. Apart from the greater design freedom, developers also have the option of integrating functional elements directly into the process, enabling certain installation and testing steps to be eliminated. The result: structural parts weighing no more than half the average for conventional components, depending on the material, with no increase in cost and comparable or superior in terms of safety.

Surface design options

In addition to purely structural parts which are not visible in the application, numerous options also exist for designing the surface of visible structural parts, which have to satisfy strength and stiffness criteria alongside the strictest look-and-feel requirements.

At a glance

Technologies at a glance

LFT and DLFT

Direct processes for manufacturing long fiber-reinforced plastic parts.

E-LFT

Patented, proprietary and affordable process for manufacturing ultra-lightweight, high-strength plastic parts. Global or local reinforcement with organo sheets, tailored fiber blanks and UD tapes.

E-LFT Hybrid

Plastic parts with local metal reinforcements. Form-closed connection between plastic and metal. The metal plate and the plastic are formed in a one-shot process in a single mold.

E-LFT Decor

Visible structural parts with a grain structure, fabrics, card webs, felts and films are produced in a one-shot process

These processes can also be combined

Advantages

Advantages of the D-LFT and E-LFT technologies

Reduced weight

Weight reduction due to the high strength and stiffness of the parts.

Economical, lightweight design

Cost benefits because local reinforcement is only provided in the areas relevant for the various load cases.

Increased strength

Proper long fibers (more than 10 mm) in the plastic part due to the gentle, direct compounding process which results in higher basic strength.

Proven welding and bonding technologies

Ideal for shell-type structural parts.

Lower tooling costs

Significantly lower tooling costs compared to conventional injection molding, with no increase in cycle times. The process can also be employed cost-efficiently for serial production of any desired quantity because at WEBER FIBERTECH even high-volume products are fully automated.

Low-stress process

Less deformation of the parts and increased temperature stability due to the low cavity pressures.

Suitable for large-sized parts

Suitable for parts up to 2 m² in size, economical production of medium-sized parts, e.g. Using family molds.

Hybrid technologies

Form-closed connection between plastic and metal. The plastic and metal are formed in a one-shot process in a single mold and a single process step. Metal plates made of steel or aluminum are inserted into the mold unmachined.

Sustainable production

All parts are completely recyclable.

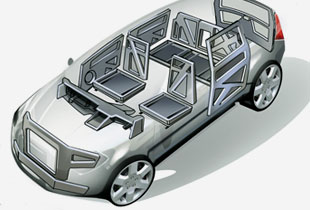

Manifold possibilities for function integration

There are manifold possibilities for integrating all kinds of functions: visible areas, fabric back compression molding, paintable, reproducible characteristics as well as inserts such as bushes or hinges.

Feasibility studies

Function-integrated lightweight design

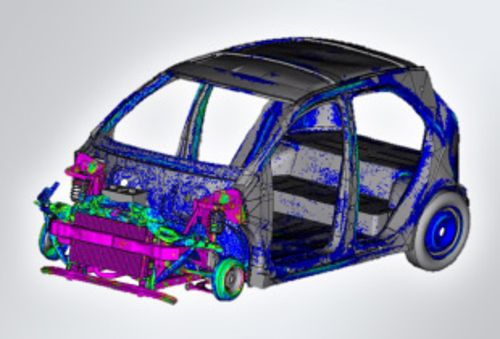

Fiber composite parts can be automatically manufactured using a variety of production processes. Which process is most appropriate and most efficient in a particular situation is determined by considering several basic parameters. For example, feasibility studies establish whether or not the envisaged technology can be effectively deployed. Furthermore, integration into existing processes and the development of a robust, efficient and reliable process chain encompassing all aspects of the production process is extremely important.

Detailed component studies have been carried out for the most diverse parts and their feasibility verified with regard to our E-LFT technology.

Applications

Considerable potential across all industries

Fiber composites have already demonstrated their considerable capabilities in many different sectors. In modern aircraft design, for instance, fiber composites have all but replaced conventional materials. Numerous innovative applications have been realized in the automotive industry, boat construction, wind power projects and the building trade.

Fiber composite technology is also very much in demand in electrical equipment, engine construction, agricultural implements and alternative energy systems, for which highly promising solutions have been identified.

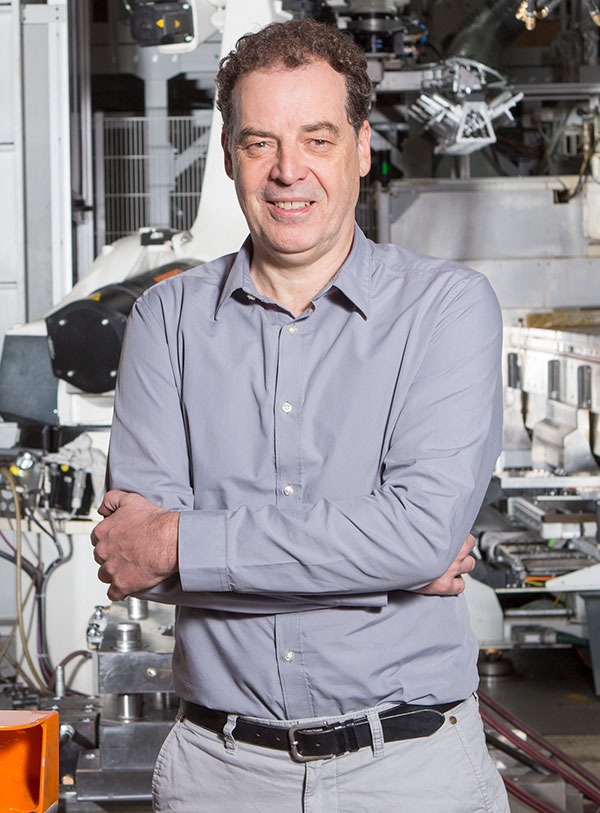

Contact us

We are a strong team – profit from our competent advice!

Are you looking for a competent cooperation partner to support your research projects? Would you like to profit from our practical experience and our vast knowledge of materials and design technology?

Contact us for more information. Our experts will be pleased to discuss the opportunities of a partnership with Weber Fibertech with you in person.

Contact

Head of Development, WEBER FIBERTECH GmbH

Norbert Stötzner

Phone: +49 7544 963 6300

Email: n.stoetzner@weber-fibertech.com